production capacity

The company has focused on the field of ozone system equipment manufacturing for 20 years and is committed to becoming a dedicated ozone system supplier. The production base has a 5000m ² standardized plant. The workshop is equipped with ultrasonic flaw detector, spectrum analyzer, four-roll plate bending machine, edge planer, submerged arc automatic welding, tube sheet automatic welding, high-speed CNC drilling machine, sand blasting and other equipment and facilities.

Through the construction of manufacturing informatization, the company promotes the reform of the company's production business process, improves production efficiency with informatization and equipment, realizes intelligent office and intelligent production, and strives to create a new modern production base with scientific and technological innovation and fast operation.

Technical strength

01

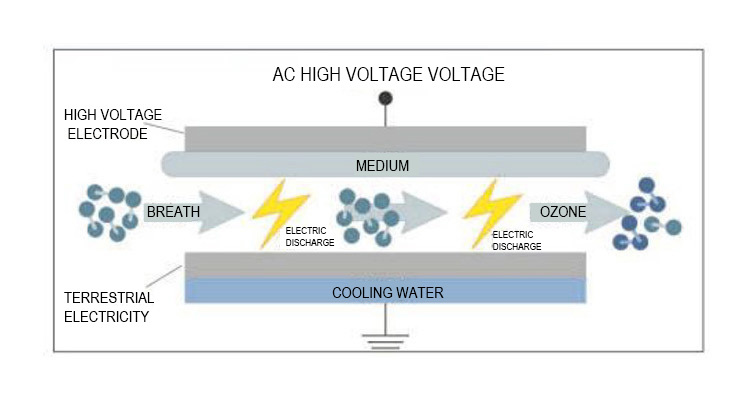

Ozone generator-core equipment

When the oxygen-containing gas passes through the discharge gap between the two electrodes, part of the oxygen molecules (O₂) will be converted into ozone (O₂) to achieve ozone production. When the high voltage electrode with high voltage, the discharge gap between the electrodes discharge, oxygen molecules are decomposed into free state oxygen atoms (O), part of the free state of oxygen atoms and undecomposed oxygen molecules recombine to generate ozone (O₂), that is, O O₂ = O.

02

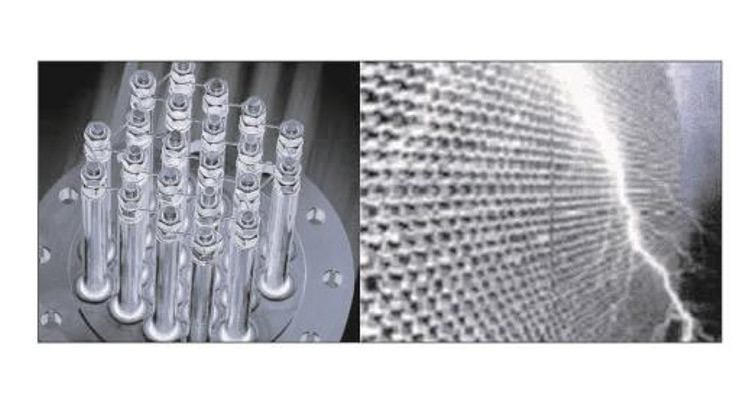

Core technology-honeycomb discharge tube

Special glass, non-glass dielectric discharge tube, good performance; discharge tube in the tank inside the honeycomb arrangement, compact structure; double gap discharge, uniform gap, improve the discharge efficiency; matching high and low voltage electrodes made in accordance with precision standards.

03

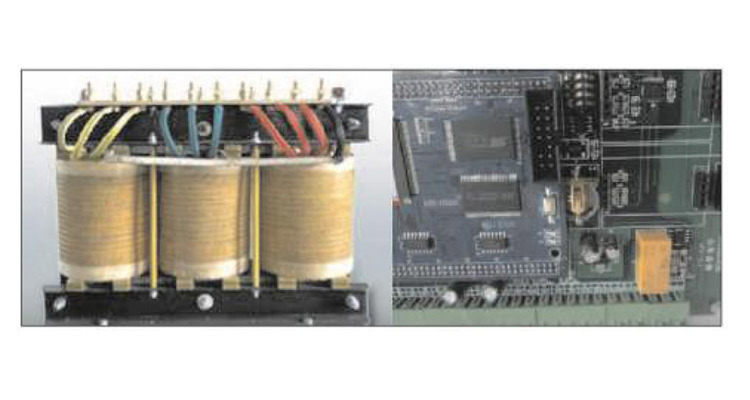

Core technology ---- 1GBT high frequency transformer

Imported IGBT power supply module is adopted, and the high frequency operation frequency of 3000-5000Hz makes the discharge ionization density larger under the same cross section. The unique DSP closed loop system communicates with the feedback signal of DCS, and automatically adjusts according to the upper and lower limits set by the user, so as to achieve the maximum energy saving purpose. The ferrite with better heat dissipation and high frequency resistance is used as the core of the transformer to increase the ozone concentration and reduce the transformer loss. Super-insulated high-voltage transformer, vacuum dipping and epoxy resin potting process, to ensure the safe operation of the transformer.

04

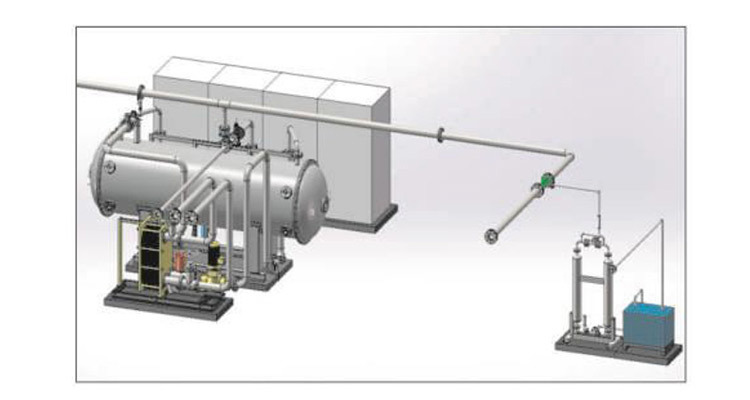

Key Technology ---- Intensive Tubular Shell Structure

Large ozone generator is composed of multiple discharge units through series and parallel structure. Form a column tube collection heat exchange device. Ontology instruments, valves and pipes are assembled in the factory and shipped as a whole; accessories and pipes are pre-assembled in the factory to reduce the installation workload on site and improve the installation quality.

05

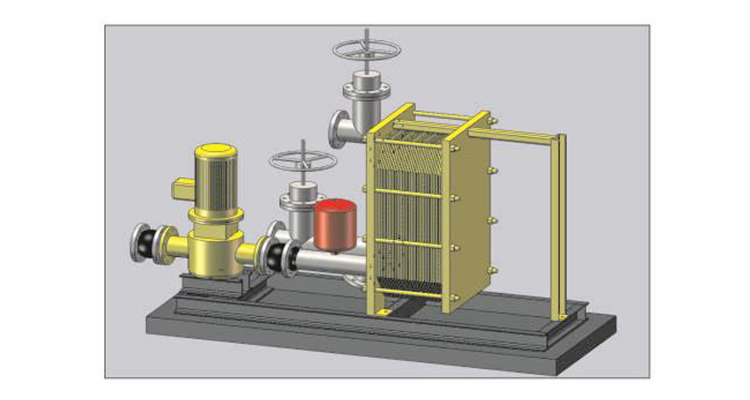

Key technology-cooling water system

Large ozone generators are mostly cooled by internal circulating water, and heat exchange is carried out with external circulating cooling water through plate heat exchanger. The internal circulation method can ensure the quality of the cooling water entering the oxygen generator, which is not easy to scale, reduce the heat exchange efficiency or corrode the discharge tube to cause leakage failure. When the cooling water temperature exceeds the system design temperature or the water is insufficient, the system will automatically send an alarm signal.